How TMT bars secure your construction projects from seismic waves? | MS Life

Hi, I am M. Mahesh, a civil engineer from Hyderabad, with 12 years of experience in house planning and elevation designing. During my tenure working in this region, I noticed that the newly constructed houses have developed cracks and lost their appeal. Plus, construction in this sandy Godavari soil region needs extra durable support to stand strong against any natural calamities. Unfortunately, people, there are not so aware of such technical issues and often deploy poor quality construction materials and TMT to save on their budget, risking the construction longevity. This is why I recommend using high-strength reinforced TMT bars …

4 Steps to assure construction quality control | MS Life

Hello everyone….! This is Gopi Krishna Yadav, civil engineer from Tandur, Telangana, with 15 years of experience in individual house planning, land surveying, and constructing multi-story projects. In Tandur, Telangana, wall cracks are fairly common whether constructing a structure or a house, even in newly constructed ones. This is owing to the presence of saline and the coastal climate, both of which have an impact on steel. To avoid these in freshly constructed structures, no compromises may be made in terms of material quality; it is critical to utilise graded and branded steel tmt bars. One thing I’ve learned over …

Keep Your Home Safe by Choosing the Right TMT Bars

When it comes to home building maintaining material quality is paramount. TMT bars for house construction are an essential component. Using TMT bars of good quality will ensure that your house lasts for generations. TMT thermomechanical treatment is a process that is used to treat the bars with heat and mechanical deformation. This treatment gives the bars higher tensile strength and makes them resistant to stress and strain. While choosing TMT bars for home building relying on the vendors to choose the right quality bars could be a bad decision. Low-cost materials will significantly lower your construction cost but will …

Key Characteristic of a Premium Quality TMT Bar

TMT bars are high intensity bars build with soft inner core and durable outer core for higher resistance and ductility. Selecting TMT bars for a construction project is not easy and knowing a suitable grade of TMT bars for a particular project is not all you need. It is important to be clear about some of the key characteristics for the right selection of bars. Most of the manufactures that produce the top 10 TMT bars in Tamil Nadu, and other neighboring states focus on meeting these characteristics in TMT bars for quality production. Bendability: The quenching process in the …

Three Key Qualities that Make TMT Bars Unavoidable in Construction

Civil and construction engineering researchers and experts have described Thermo-Mechanically-Treated iron rods as the strongest iron rods for infrastructure. Builders prefer TMT iron rods because of the combination of tensile strength and ductility they offer, as well as the fact that they are more corrosion-resistant than local iron rods. This is due to the quick quenching and tempering techniques used in their production process. The top TMT bars manufacturers in Hyderabad have products that are immune to earthquakes due to their tensile strength and ductility. Over the years, natural disasters such as earthquakes, storms, floods, tsunamis and more had devastated …

Construct for the future with TMT Bars

Whenever you find a building under construction, the first thing that you notice is the heaps of TMT bars stacked up at the site. These thermo mechanically treated bars are extremely strong, ductile, and corrosion resistant. If you want your structure to last for years, using TMT bars is a wise decision. Let us understand what top TMT bars manufacturers in Tamil Nadu observe as the ideal qualities in TMT bars. TMT bars are processed by high technology and display enduring tensile strength that help in supporting tall building structures, prevents damage from seismic motions(earthquake) and are known for their …

All about TMT Bars Exclusively For Seismic Zone

Geographical surveys suggest that India has mainly four seismic zones namely – zone 2 (least active), zone-3 (moderately active), zone-4 (high), and zone-5 (highest earthquake prone). Strikingly, the last two zones comprise 54% of the lands in India making the regions vulnerable to earthquakes. For these regions, construction needs to be strong enough to resist earthquakes, and MS Life has the perfect solution for the same. TMT bars, manufactured in our integrated steel plant, are what we would suggest using in seismic zone buildings. What makes TMT bar the best choice for earthquake resistance? Best quality and the right grade …

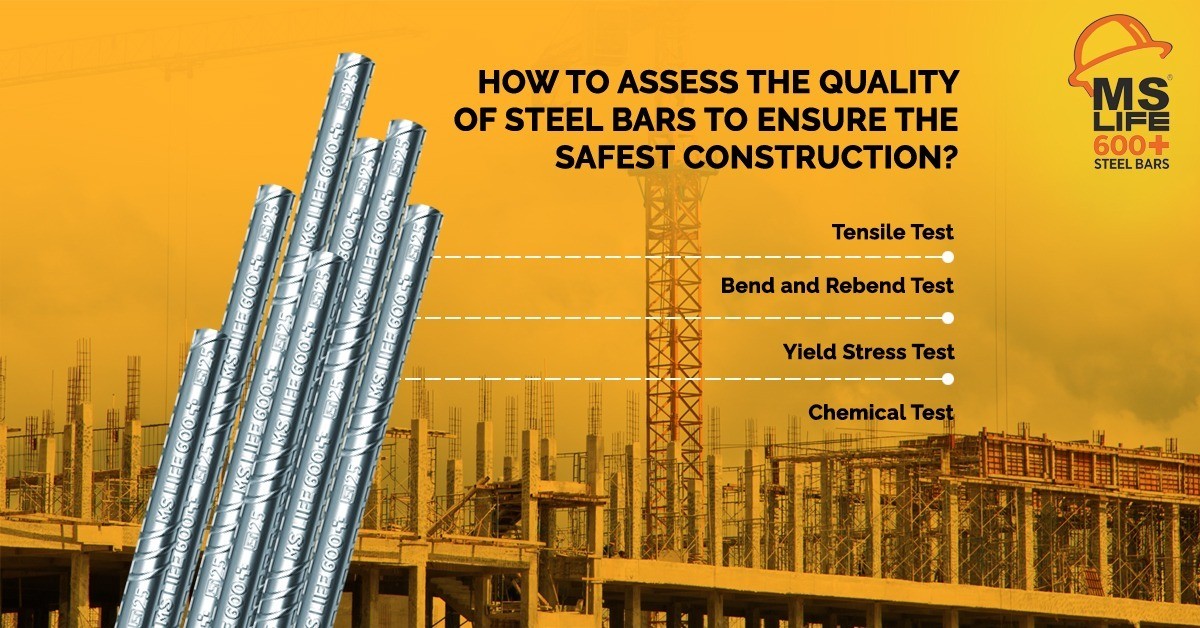

How To Assess The Quality Of Steel Bars To Ensure The Safest Construction?

Best quality TMT bars are the ones that ensure flexibility, strength, and longevity. As per the IS Standards, Fe 600 grade steel reinforcement bars have these properties and stand out as the best quality steel bars. In all types of constructions, be it residential or commercial, the best quality TMT bars are highly recommended by the largest steel companies in India. And how to ensure that the TMT bars are of the best quality? There are certain tests that determine the elongation properties, strength and overall quality of the TMT bars. a. Tensile Test TMT bars with capacity of 32mm …

TMT or HYSD: Which Bars Are Better For a Safer Home

TMT or Thermo Mechanical Treatment is a process that uses both heat treatment and mechanical deformation. These bars tend to have higher tensile strength and stress resistance. HYSD or High Yielding Strength Deformed are steel rods made with heat treatment. While applying heat, the bars are cold twisted for shaping. Steel bars used to be low on tensile strength and fragile hence did not garner much attention. Upon the release of HYSD bars, they became popular because of their residual stress, weldability, and corrosion resistance properties. However, over the years, the construction industry has seen a meteoric rise in popularity, …

Why Are TMT Bars the Ideal Material for a Sustainable Future

Just like every other industry in the world, the steel industry has also seen its share of improvements in the technological and research front over the past decade. Over half of the steel products that are in current use, was not in existence ten years ago. This alone is a proof of the drastic developmental strides this industry has witnessed. Historically speaking, the steel industry has always been associated with environmental destruction and as a menace to the atmosphere. However, the major advancements in the field of technology, has allowed steelmakers all over the globe to pick up more eco-friendly …